Brake Disc Drum Tooth Coupling

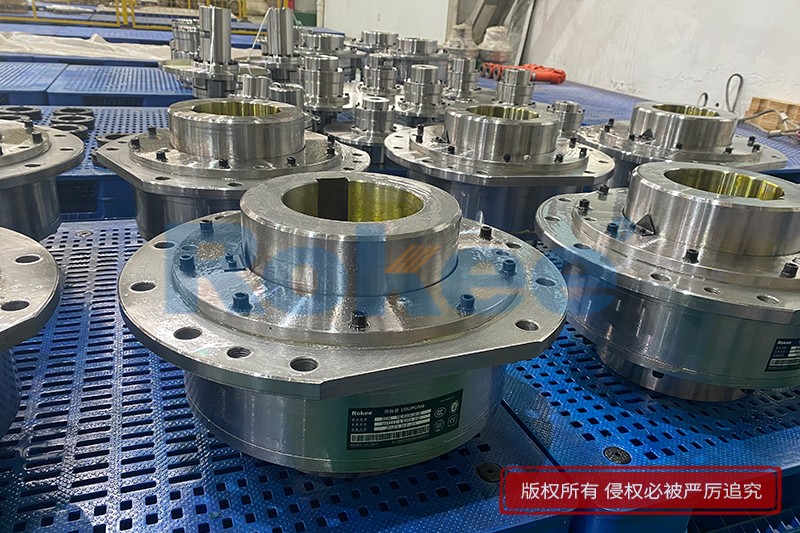

Rokee® is a Brake Disc Drum Tooth Coupling Supplier from China, customized brake disc drum tooth coupling according to the drawings which provided by the customer, selling chinese national standard brake disc drum tooth coupling, support export, due to excellent quality, complete technical services and superior cost performance, Rokee® industrial coupling have been serving more than 60 countries and regions in the world, effectively operating in many corners of the world.

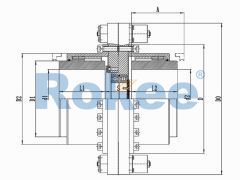

The Drum Gear Coupling is a specially designed advanced Gear Coupling. Its outer teeth are made into a sphere, with the center of the sphere on the axis of the gear. The teeth clearance is slightly larger than the general products and can transfer a greater torque and allow greater angular displacement, enjoying excellent performance and longer life.

ROD Curved-tooth Gear Coupling is one of the transmission products with core technology independently developed by Rokee and has established and reported corporate technical standards in the country. By combining with the standard coupling technology of advanced countries such as Japan and Germany, we optimized many detailed dimensions, and adopted the toothed design with a large pressure angle and short shaft design for the shaft hole, which reduces the length-diameter ratio, and has a more compact structure and excellent speed performance.

The bolts of similar types are standardized and the parts are universal. Compared with the national standard couplings, our Toothed Couplings can transfer more torque, with greatly reduced mass and small moment of inertia. It meets the European explosion-proof requirements and the comprehensive performance is greatly advanced. We highly recommend you to choose our Crown Gear Couplings for better transmission performance.

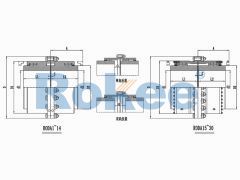

RODA Drum Gear Coupling

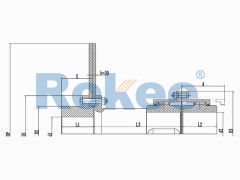

The RODA Drum Gear Coupling is the basic type of ROD series coupling, suitable for most situations where the compensation of transmission distance and motion position does not require special increase.RODT Indirect Tube Drum Gear Coupling

The RODT Drum Gear Coupling is an extended type of ROD series coupling, suitable for increasing transmission distance.RODX Intermediate Shaft Drum Gear Coupling

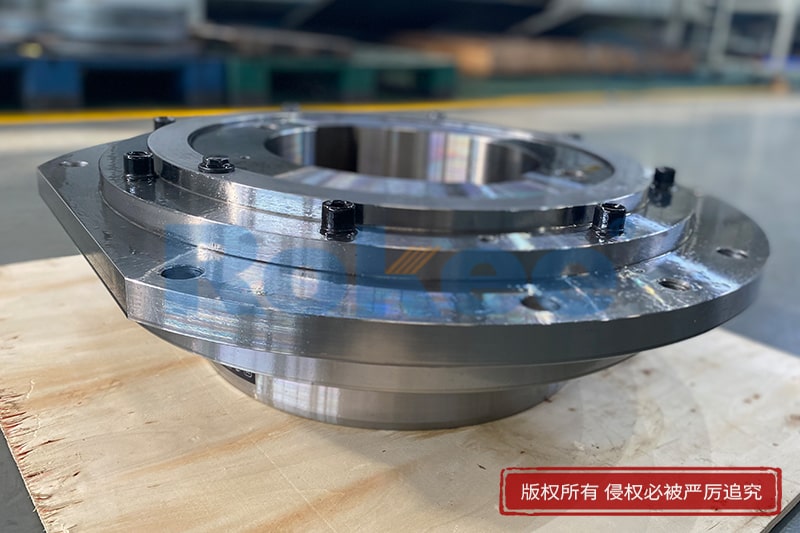

RODX Drum Gear Coupling is an extended type of ROD series coupling with a floating shaft design in the middle, suitable for increasing transmission distance.RODP Brake Disc Drum Gear Coupling

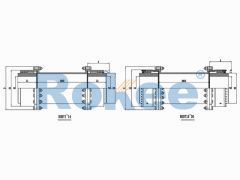

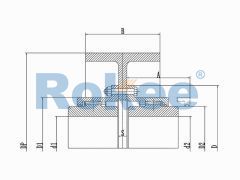

The RODP Drum Gear Coupling is a type of ROD series coupling with a brake disc, suitable for transmission situations where braking needs to be used in conjunction with disc brakes.RODF Split Brake Disc Drum Gear Coupling

The RODF Drum Gear Coupling is a type of ROD series coupling with split brake discs, suitable for transmission situations where there is braking demand and the braking position changes when used in conjunction with disc brakes.RODW Brake Wheel Drum Gear Coupling

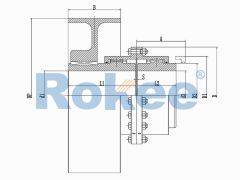

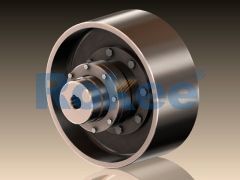

The RODW Drum Gear Coupling is a type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes.RODU Brake Wheel Drum Gear Coupling

The RODU Drum Gear Coupling is another type of ROD series coupling with brake wheels, suitable for transmission situations where braking needs to be used in conjunction with wheel brakes and applied to one end of the axle, achieving smoother and more reliable braking performance.RODV Vertical Installation Drum Gear Coupling

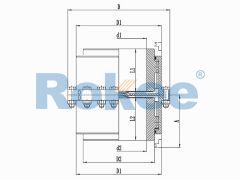

The RODV Drum Gear Coupling is a vertical installation type of the ROD series coupling, suitable for transmission situations that require vertical transmission torque.RODM Torsion Protection Drum Gear Coupling

The RODM Drum Gear Coupling is a torque setting form of the ROD series coupling. By adjusting relevant components, the maximum transmission torque can be easily set within a certain range. Suitable for shafting transmission situations that require safe torque operation to protect important machine components from excessive damage.

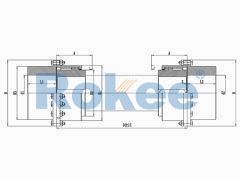

GICL Drum Gear Coupling

GICL drum gear coupling has larger inner teeth width, which can transfer torque while compensating for larger axial displacement.GICLZ Drum Gear Coupling

Half of the GICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement.GIICL Drum Gear Coupling

GIICL drum gear coupling has small inner teeth width, which can transfer torque while compensating for small axial displacement. Also, its structure is compact and the moment of inertia is low.GIICLZ Drum Gear Coupling

Half of the GIICLZ drum gear coupling adopts a non-toothed semi-coupling sleeve structure, which is usually connected in pairs or used in occasions with small angular displacement. Also, its structure is compact and the moment of inertia is low.GCLD Drum Gear Coupling

GCLD drum gear coupling is generally used for direct connection with the motor, so it generally has a higher speed and compact structure.NGCL Drum Gear Coupling

NGCL drum gear coupling is designed with a brake wheel, suitable for situations where braking is required.NGCLZ Drum Gear Coupling

NGCLZ drum gear coupling is designed with a brake wheel, suitable for situations where braking is required. Half of its structure adopts a semi-coupling sleeve design, with smaller angular displacement compensation but more stable braking.WG Drum Gear Coupling

The overall characteristics of WG drum gear coupling are similar to those of other drum gear couplings, but with a larger modulus design, which can generally transmit greater torque.WGZ Drum Gear Coupling

WGZ drum gear coupling is designed with a brake wheel, suitable for shoe type braking.WGP Drum Gear Coupling

WGP drum gear coupling is designed with a brake disc, suitable for disc type braking.WGT Drum Gear Coupling

WGT drum gear coupling is designed with indirect tube, suitable for long distance torque transfer.WGC Drum Gear Coupling

WGC drum gear coupling is specially designed for situations where vertical transmission is required, suitable for some vertical transmission systems.WGJ Drum Gear Coupling

WGJ drum gear coupling is designed with intermediate shaft, suitable for long distance torque transmission, and some are equipped with axial buffers.

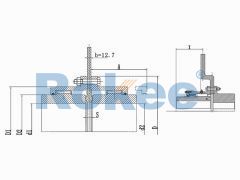

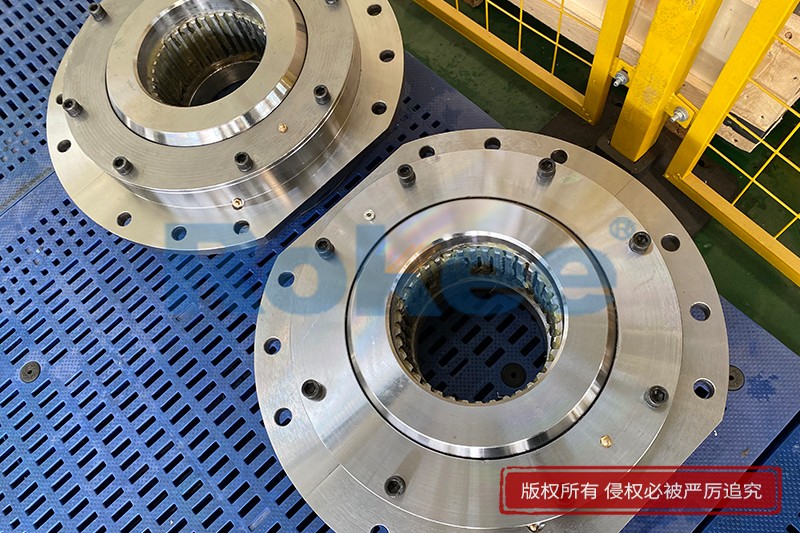

The drum coupling is the crane drum coupling. The internal sphere gear sleeve is assembled with the external drum perfectly. Relying on the specially designed key, the external sphere shaft sleeve forms the entirety with gear sleeve perfectly. It will promote the reliable connection of reducer shaft and drum and it is the most ideal product in the market home and abroad at present.

RWC series drum coupling is a type of high-performance drum coupling developed by us and mainly applied for port lifting and large mechanical lifting. In comparison with international DC series products, it has identical outline and connection size, but its interior design is more thorough and steady. The hook face of gear is optimized and the large pressure angle design is applied. A patented mechanism is used for the sealing. One-time filling of lubricating grease is basically free from maintenance, solving maintenance difficulty at heights. In addition, an electronic warning device is set. When the wear life reaches the safe position, the weak current connection will trigger the alarm immediately. It’s a good choice for you!

RWC Ball And Drum Gear Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.WZL Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure.DC Drum Coupling

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load.WJ Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load.WJA Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.

« Brake Disc Drum Tooth Coupling » Post Date: 2023/9/22

URL: https://www.rokeecoupling.com/en/blog/brake-disc-drum-tooth-coupling.html

Tags: Curved Tooth Couplings,