Ball Joint Type Drum Couplings Processing

Rokee is a Drum Coupling Manufacturer from China, design & custom-made drum coupling with reasonable price and high-end quality, learn more about ball joint type drum couplings processing information, please email us, Rokee's technical engineer will reply as soon as possible.

The Cardan Universal Coupling uses cross bearings to connect the flanges at both ends, which can transmit torque that is not on the same axis. The diagonal compensation can reach more than 25°, and the spline connection can compensate for the axial displacement in a large distance. With high carrying capacity and excellent transmission efficiency, it is widely used in modern industrial fields.

SWC Universal Shaft adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. It is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.

SWP Universal Coupling adopts integrated fork head layout. Similar to the use of the SWC universal coupling, it is mainly used in the field of heavy-duty large equipment, with a rotary diameter of up to 1200mm.

Our Universal Joint Couplings are widely used and have many impressive records. From micro products for modern logistics, artificial intelligence machinery, light products used in the paper industry, high speed and high performance products for engineering and railway vehicles, to super heavy duty products used in metallurgical rolling system systems, Rokee has won us with mature products and quality Long-term trust of customers, widely exported to Europe, America and other parts of the world.

All standard Cardan Couplings of Rokee are optimized design products based on the combination of decades of experience and computer design technology.,The products we are proud of are not only different from the national technical standards of China but also the standards of other manufacturers in the world. Unique design ideas and make perfection more perfect sprit drive our products find a better balance between lower price and rotational and transmission torque performance.

Rokee's standardized products also mean faster delivery and easier spare parts availability as well as quick maintenance service.

The Cardan Shaft products used in important equipment and core industrial fields have not only undergone careful design, but also comprehensive torque, stiffness, balance performance and life tests.

SWC-BH Standard Telescopic Welded Universal Coupling

SWC-BH Universal Coupling adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. SWC-BH Cardan Shaft is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.SWC-CH Long Telescopic Welded Universal Coupling

SWC-CH Universal Coupling adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. SWC-CH Cardan Shaft is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.SWC-DH Short Telescopic Welded Universal Coupling

SWC-DH Universal Coupling adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. SWC-DH Cardan Shaft is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.SWC-WD Non-telescopic Short Universal Coupling

SWC-WD Universal Coupling adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. SWC-WD Cardan Shaft is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.SWC-WH Non-telescopic Welded Universal Coupling

SWC-WH Universal Coupling adopts integrated fork head layout, with the rotary diameter of 1600mm and torque transmission distance of more than 30m. SWC-WH Cardan Shaft is widely used in steel rolling machinery, crane transport machinery and other heavy equipment fields.SWP-A Universal Coupling

SWP-A Universal Coupling adopts integrated fork head layout. Similar to the use of the SWC universal coupling, SWP-A Cardan Shaft is mainly used in the field of heavy-duty large equipment, with a rotary diameter of up to 1200mm.SWP-B Universal Coupling

SWP-B Universal Coupling adopts integrated fork head layout. Similar to the use of the SWC universal coupling, SWP-B Cardan Shaft is mainly used in the field of heavy-duty large equipment, with a rotary diameter of up to 1200mm.SWP-C Universal Coupling

SWP-C Universal Coupling adopts integrated fork head layout. Similar to the use of the SWC universal coupling, SWP-C Cardan Shaft is mainly used in the field of heavy-duty large equipment, with a rotary diameter of up to 1200mm.SWP-D Universal Coupling

SWP-D Universal Coupling adopts integrated fork head layout. Similar to the use of the SWC universal coupling, SWP-D Cardan Shaft is mainly used in the field of heavy-duty large equipment, with a rotary diameter of up to 1200mm.

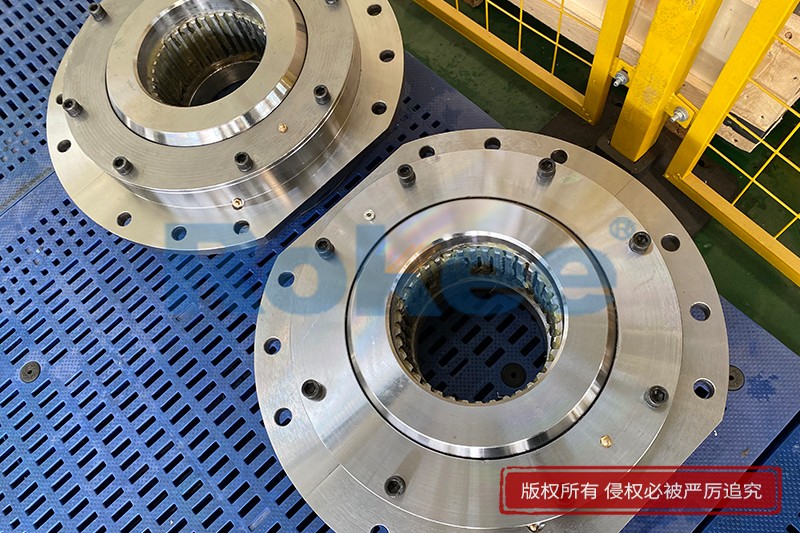

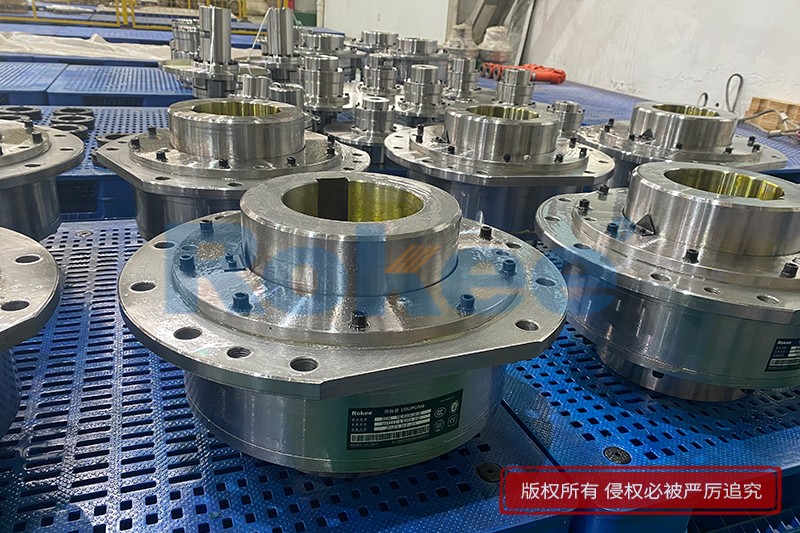

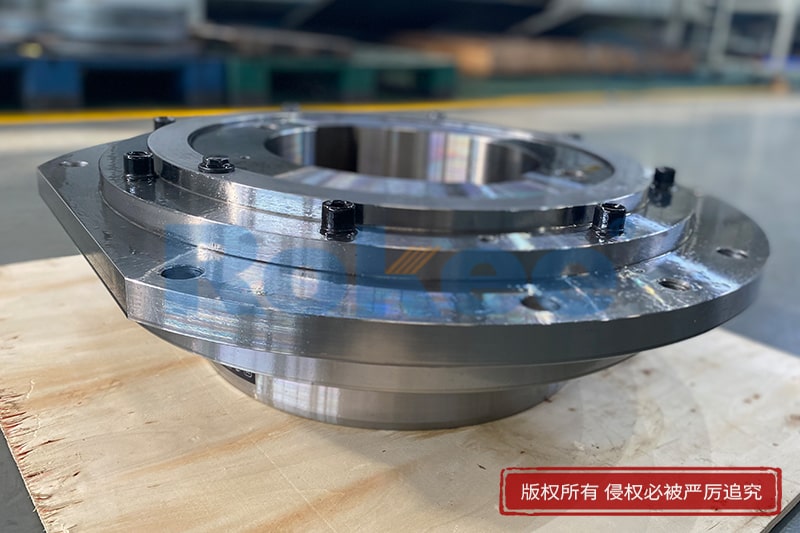

The drum coupling is the crane drum coupling. The internal sphere gear sleeve is assembled with the external drum perfectly. Relying on the specially designed key, the external sphere shaft sleeve forms the entirety with gear sleeve perfectly. It will promote the reliable connection of reducer shaft and drum and it is the most ideal product in the market home and abroad at present.

RWC series drum coupling is a type of high-performance drum coupling developed by us and mainly applied for port lifting and large mechanical lifting. In comparison with international DC series products, it has identical outline and connection size, but its interior design is more thorough and steady. The hook face of gear is optimized and the large pressure angle design is applied. A patented mechanism is used for the sealing. One-time filling of lubricating grease is basically free from maintenance, solving maintenance difficulty at heights. In addition, an electronic warning device is set. When the wear life reaches the safe position, the weak current connection will trigger the alarm immediately. It’s a good choice for you!

RWC Ball And Drum Gear Drum Coupling

The ball and drum gear drum coupling is a drum coupling developed by Rokee with a more reliable structure, higher compensation ability and higher safety factor. The outer sleeve adopts a spherical drum tooth design, which has low requirements for shafting installation accuracy, large transmission torque, strong overload capacity and can withstand great radial load. The connection size is the same as that of DC series, but the bearing capacity is increased by more than 30%. The innovative spherical sealing technology makes this type of product maintain excellent lubrication and greatly improve its service life.WZL Drum Coupling

WZL Drum Coupling is a spherical hinged coupling. It has a connecting flange with an inner spherical surface, a spherical semi-coupling sleeve with an outer spherical surface, a special transmission key, an inner and outer limit cover, etc. The internal control generally adopts the splined sleeve design, which transmits torque through a specially designed key bar and can withstand large torque and radial load. The maximum angular displacement compensation can reach 3°, with a life indicator and safe and reliable structure.DC Drum Coupling

DC Drum Coupling is designed with drum teeth, which is used for connecting the reducer of crane transmission system with the drum. It can bear radial load and transfer large torque, but cannot transfer axial load.WJ Drum Coupling

WJ Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load.WJA Drum Coupling

WJA Drum Coupling is a spherical roller coupling, which is composed of jacket with connecting flange, spherical roller, semi-coupling, inner and outer cover plate and sealing system, capable of transmitting large torque and bearing radial load. The connection between the coupling and the output shaft of the reducer adopts an involute spline pair design.

« Ball Joint Type Drum Couplings Processing » Post Date: 2023/10/18

URL: https://www.rokeecoupling.com/en/blog/ball-joint-type-drum-couplings-processing.html

Tags: Brake Drum Couplings,